NIR-O™ NIR Process Analyzer – Spectrometer

GUIDED WAVE’S NIR-O process analyzer offers remote multichannel extended range near-infrared (1000-2100nm) spectroscopic analysis. NIR-O provides excellent signal-to-noise ratio, wavelength stability, NIST traceable wavelength calibration, dual beam optics and built-in diagnostics. Process engineers, operators, and researchers will appreciate NIR-O’s ability to monitor up to 12 process streams or sample interface points within a stream with accuracy, repeatability, and reliability. Additionally, the optional Stability Monitor System can provide confidence in hardware performance in the field.

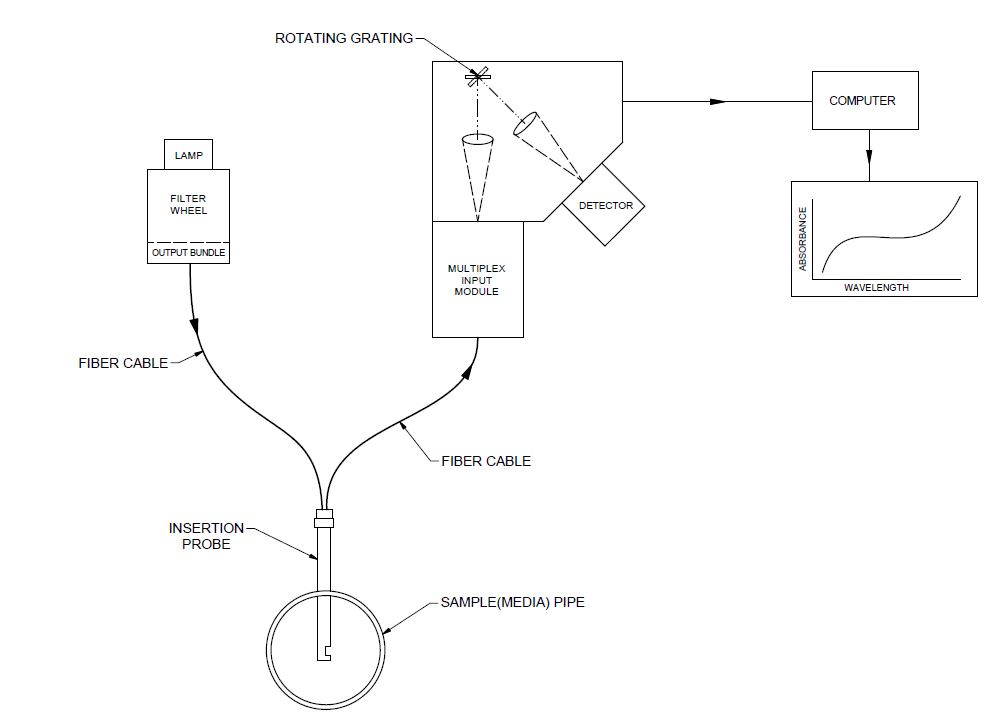

Complete Analyzer System

NIR-O is the core of a comprehensive process analyzer system that includes the spectrometer, one or more NIR probes, fiber optic cables, and OmniView™ scanning and analysis software. Like our previous Guided Wave spectrometers, NIR-O uses infrared radiation to collect spectral data from liquids, gases, glass, and polymer-based films. The spectral data are interpreted by the OmniView software to determine the composition or physical characteristics of the material.

Real-Time Measurements

Using intrinsically safe fiber optic cables to transmit light from the spectrometer to your process and back, allows real time measurements at any time, providing you with up-to-date process information. NIR-O is designed to be used with Guided Wave’s 500 μm core jacketed fiber optic cables. These unique cables contain a high purity fused silica core fiber, surrounded by specialized jacketing to protect both the signal transmitted and the fiber itself, allowing the analyzer to be located up to two hundred meters away.

Designed for Online Processes

NIR-O is suitable for online analyses of most processes and process streams. Having the built-in capacity to add more sampling points (up to 12 total channels) within the same process or across processes, in any combination, gives you the flexibility to invest in exactly the capacity you require now. It also minimizes investment for any expansion you may want in the future. NIR-O is compatible with all Guided Wave probes and flow cells which can be used in any combination required for your analytical needs. NIR-O operates in the xNIR range of 1000-2100nm, using process-proven TE-cooled InGaAs detector technology. Built-in Modbus TCP over Ethernet allows easy communication with your system. NIR-O is rugged and robust for process installations.

Figure 1: NIR-O How it Works

True Multiplexing

NIR-O can be configured for up to 12 channels (i.e., independent sample points). This allows you to incorporate the number of sampling points you need now, while being able to easily and more economically add sampling points as your process or facility needs change. NIR-O can measure multiple parameters at up to 12 independent sampling locations in rapid succession, using a solid state detector by employing digital optical switching technology. Multiplexing greatly reduces the cost-per-measurement point, making cost-per-result more economical.

Research-Grade Signal-to-Noise Ratio

NIR-O’s dual-beam design, coupled with its high output near-zero aberration scanning grating, puts more light into the fiber. This provides an excellent signal-to-noise ratio, which means better sensitivity in your measurements. Each NIR-O provides excellent wavelength accuracy (NIST traceable) and superb wavelength repeatability.

Common Online Applications/Analyses

Polyols: OH (hydroxyl) and acid number

Polymers: reaction endpoint, co-polymer ratio

Films: thickness, %T, %R

Measurement of moisture content

Refinery products; RON, MON, RVP, Distillation Points, Olefins, % Oxygen

Vinyls: solvent composition

Process research and development

Options

- Touch screen computer for local process visualization and control (only on general purpose and Z-purge package)

- Z-Purge package: Class 1 Zone 2 Groups IIB+ H2 ATEX , IECEx certification

- X-Purge package: Class 1 Zone 1 Groups • IIB+ H2 ATEX, IECEx certification

- Camo Unscrambler® chemometrics software

- Support for popular prediction engines

- Remote desktop computer

- External 4-20mA analog I/O box, custom configured for your needs

- Starter Library models for Refinery Applications

- Chemometric modeling support available

- FAT/SAT support available

- Chemometric and/or instrument maintenance training

- WaveCare extended warranty and premium support packages