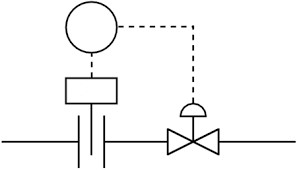

Viscometer inline, online, in tank, at line

POLYMERS & CHEMICALS

OUR SOLUTIONS ALLOW:

To increase production through time cycle optimization.

Better end-point detection.

Easier monitoring.

Prevention of mass solidification.

Reduction of costly and time-consuming laboratory sampling.

One single sensor able to provide high level of sensitivity over a very large measurement range.

MAIN advantage:

You can follow a wide span reaction with one single sensor thanks to its unsurpassed sensitivity.

OIL & ENERGY

OUR SOLUTIONS ALLOW:

A single sensor able to provide instantaneous measurement and efficient analysis: dynamic and kinematic viscosity, density and temperature.

Avoids drift during manufacturing and guarantees end-product quality.

Processor directly calculates Viscosity at Reference Temperature (TCV: Temperature Compensated Viscosity).

Correlated to the ASTM standards.

Works without maintenance and has no wearing parts.

Viscosity meter resistant to high-pressure and high-temperature environments (HPHT).

MAIN advantage:

From Kerosene to Bitumen, monitor your process

with a sensor that never clog.

FOOD & BEVERAGE

OUR SOLUTIONS ALLOW:

A viscosity sensor specially designed for sanitary environment (according to 3A specifications) with no niche spaces.

Increased safety by avoiding contamination and bacteria proliferation.

Clean-in-place design (CIP), no need to uninstall it from the process.

Corrosion resistant (316L SS) and compatible with sanitizing procedures.

Many mounting positions to avoid dead spaces.

High pressure version and/or electropolish finishing available.

MAIN advantage:

Just a 316L needle is inserted in your process.

COSMETIC, PHARMA & BIOTECH

OUR SOLUTIONS ALLOW:

A viscosity sensor specially designed for SANITARY environment (according to 3A specifications) with no niche spaces.

Increased safety by avoid contamination and bacteria proliferation.

Clean-in-place design (CIP), no need to uninstall it from the process.

Corrosion resistant (316L SS) and compatible with sanitizing procedures.

Many mounting positions to avoid dead spaces.

High pressure version and/or electropolish finishing available.

MAIN advantage:

Just a 316L needle is inserted in your process.

COATINGS

OUR SOLUTIONS ALLOW:

Provide coating and painting quality and consistency through homogeneity and uniformity.

Continuously deliver viscosity and temperature information.

Are compatible with solvents and water-based formulations.

Are very tolerant to particles.

Can easily be connected to controllers and installed on coating circulation loops.

Contain no wearing parts and require very low maintenance.

MAIN advantage:

Not affected by particles or bubbles.

Viscometer inline, online, in tank, at line.