Measuring technology for flow rate, mass flow rate and flow velocity

Our measuring instruments are applicable at high pressures up to 50 bar. Their unique strength lies in hazardous areas, in aggressive media, gases with temperatures up to 550° C, high flow velocities up to 200 m/s or in pipe flows with changing gas compositions or flow direction. They deliver precise measuring results even with smallest flow measuring velocities and lowest volume flows. In sample gases such as ammonia, butadiene, hydrogen, LPG, natural gas, propane and many other media. Höntzsch measuring instruments deliver exact values. Our flow sensors are applied even under toughest circumstances such as strong pollution or dust pollution.

Anemometer for flow measurement

For measuring in pipelines and ducts, aerodynamic research, test bench measurements, measuring laminar flow, landfill gas, exhaust gas, flow rate and flow velocity in flowing waters.

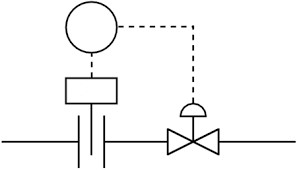

Vortex meter

For the measuring of flow rate, landfill gas and other gases, it is also suited for the measuring in wet and particle-laden gases and for the flow measurement of sludge aeration air, sewage gas and water vapour. Further possible applications are the flow measurement in climatic wind tunnels and the measurement of engine intake air on test benches.

Flow sensors and flow meters

Thermal flow sensors and calorimetric flow meters for fixed or portable consumption measurement in gases. They’re also suited for the following applications: measuring of laminar flow, burner supply air and mass flow.

Portable ultrasonic flow meter for liquids

Ultrasonic pulses are sent and received simultaneously through the medium in the direction of flow and against it, guaranteeing accurate measuring results within minutes. They are easy to install and operate and there is no process interruption or pipe restrictions. As a result there is no pressure loss.

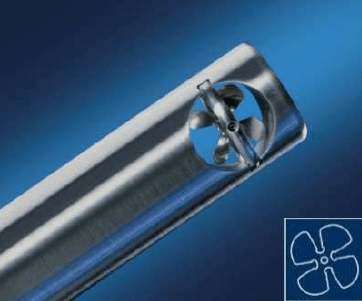

Vane Wheel FA

Flow rate and flow velocity in pipes and ducts, measuring flow profiles, aerodynamic research, measuring laminar flow, also at high gas temperatures, landfill gas, exhaust gas, flow rate and flow velocity in flowing waters.

Vane Wheel Flow Sensors

• Insertion probes or measuring tubes

• For measuring in air/gases and water/liquids;

measuring range in air/gases 0.2… 150 m/s

• Medium temperatures up to 550°C

• Negligible pressure loss

• Resistant to aggressive gases

• Sensing the +/- direction of flow

•Profibus

•Applications in Ex atmospheres

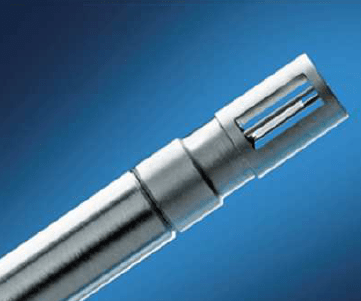

Thermal TA

Fixed and portable measurement of consumption quantity in compressed air and other clean gases; Measurement of laminar flow in clean rooms, under fan-filter-units; flow measurement in production facilities of the pharma-; food-processing- and semiconductor industry as well as flow-monitoring in glove boxes, isolators or sedimentation rate measurements in spray booths. Measurement of burner air and leakage flow; Monitoring of safety-relevant facilities – in aerospace as well as boats and ships.xhaust gas, flow rate and flow velocity in flowing waters.

Thermal Flow Sensors TA

Electrically heated sensor element

The heat flow on the ambient gas determines the mass flow,

flow velocity and standard flow rate

Insertion probes or measuring tubes

Gas mass flow-proportional measuring in air, nitrogen, natural gas,

argon, helium, propane, butane, CO₂, …

Working temperatures up to 140 °C

Standard flow velocity 0.2 … 200 m/s; standard flow rate from 0.4 m³/h

Turndown ratio up to 1:1000

Time constant just 1 s

Applications in Ex atmospheres

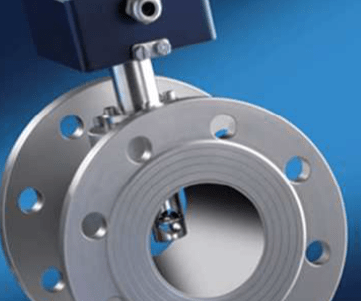

Vortex VA

Flow rate and flow velocity measurement in wet and/or particulate-laden gases, biogas or exhaust gas, also according to Clean Air Guidelines, (TA Luft). Flow rate measurement of sludge aeration air, sewage gas, landfill gas, water vapour and engine intake air on test stations. Flow velocity in climatic wind tunnels, diluted car exhaust gas, traffic tunnels and in nuclear reactor technology.

Vortex Flow Sensors VA

Shedding frequency determined by ultrasonic field

Insertion probes or measuring tubes

For determining flow velocity and flow rate of air/gases

Working temperatures up to 240 °C

Negligible pressure loss

Initial value just 0.5 m/s

No moving parts

Long-term stability by "digital measuring“

Applications in Ex atmospheres

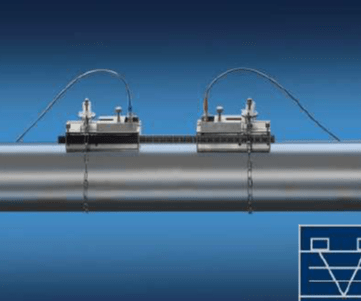

Ultrasonic UA

This principle of measurement is also referred to as the transit time difference method. For measuring the flow rate of liquids using this technique, ultrasonic pulses are sent and received simultaneously through the medium in the direction of flow and against it. The sensors work alternately as transmitter and receiver. The transit time of the acoustic signals filtered through the medium in the direction of flow is shorter than that against it. The difference in transit time Δt is measured and can be used to calculate the average flow velocity of liquids filtering through the acoustic path. After measuring the flow velocity and with the pipe cross-sectional area, volumetric flow can be calculated.

Ultrasonic Flow Meter

• Water, diesel, petroleum products, glycol mixtures, …

• with a measuring range of 0.1 … 20 m/s

• For pipeline cross sections 13… 2000 mm

• Non-invasive measurement of liquids in pipelines and ducts

• Sensing the +/- direction of flow

Portable handheld flowtherm NT/Ex

Display of up to three values

Storage of up to 100 measuring points or user profiles

Data logger for storing up to 40.000 values

Multifunctional analog inputs 0-10 V / 4–20 mA

Two analog outputs 0-10 V

USB interface for downloading logged data

IP65 type of protection